Alumina PCBs for Satellite

Alumina PCBs are a specialized printed circuit board (PCB) substrate material that caters to high-performance applications and demanding environments. Alumina provides superior gas tightness, electrical insulation, thermal conductivity, and stability at elevated temperatures that surpass the performance capabilities of standard organic FR-4 substrates. This makes them ideal for use in satellite communication systems, hybrid microelectronics, electronics packaging and multi-chip modules.

Alumina circuit boards are fabricated by applying metallized circuits to a sintered aluminum oxide ceramic base plate, which is then laminated and densified in a high-temperature furnace. Single-layer alumina PCBs have copper foil layers that can be as thick as 1oz-10oz. Alumina substrates have excellent conductivity, meaning the copper can carry large current loads without heating up or causing thermal failure.

The insulating dielectric layer serves to isolate the copper from the alumina pcb, and this helps to dissipate heat generated by electronic components. The alumina also has very good electrical insulation properties that ensure the copper can operate safely in the presence of high voltages, which is essential for satellite communications.

Alumina PCBs for Satellite Communication Systems

Alumina substrates also have high chemical and mechanical resistance to damage, which is important for military and aerospace applications, where abrasion and corrosion can be an issue. They also have a high hardness rating on the Mohs scale of 9, which makes them very tough and durable, especially when exposed to harsh environments.

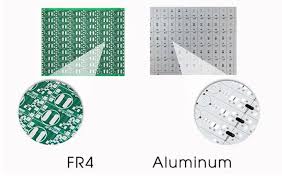

FR-4 is the common substrate material used in most consumer and commercial electronics, and it offers a good balance of cost, performance and fabrication ease. However, for high-performance applications and demanding environments that push the limits of organic FR-4 substrates, alumina ceramic is an excellent alternative.

Some of the key benefits of alumina PCBs include their ability to operate in hostile environments at elevated temperature levels, excellent electrical and thermal performance and resistance to high humidity, all of which makes them an ideal choice for satellite communication systems. They can also support high frequency circuits, due to their low loss and good conductivity properties. The electrical strength of alumina is also very high, allowing it to withstand higher electric field strengths than FR-4, which is an important feature for high-speed data transmissions.

In addition to these superior properties, alumina has a lower coefficient of expansion than other substrate materials, which is another benefit for high-temperature applications. This means the circuits can be flexed and bent without suffering any structural damage, which is particularly useful for mobile devices such as tablets and smartphones.

There are many other advantages of alumina PCBs, such as their high-speed performance and the fact that they can be made with smaller line widths and spaces than conventional FR-4 boards. They can also be drilled, etched and soldered using traditional techniques. In order to achieve the best possible results, it is advisable to consult with an experienced and reliable supplier such as Viasion.